Materials for pressure sensitive adhesive (PSA) systems:

Pressure Sensitive adhesives must be applied with pressure. Anything that pressure would not be considered PSA tape. Other types of adhesive may require a solvent, water, or heat to activate the adhesive. The quality of PSA is evaluated by parameters such as tack, peel and cohesion.

All types of PSA which could be supplied by Kimya Exir ARISA are categorized as below:

| Polymer solution: 1.acrylic 2. Silicone 3.natural/synthetic rubber | |

| PSA | Water based polymer dispersion: 1.acrylic 2. natural/synthetic latex |

| Hotmelt: 1. Acrylic UV-curable 2. synthetic rubber |

Release Agent:

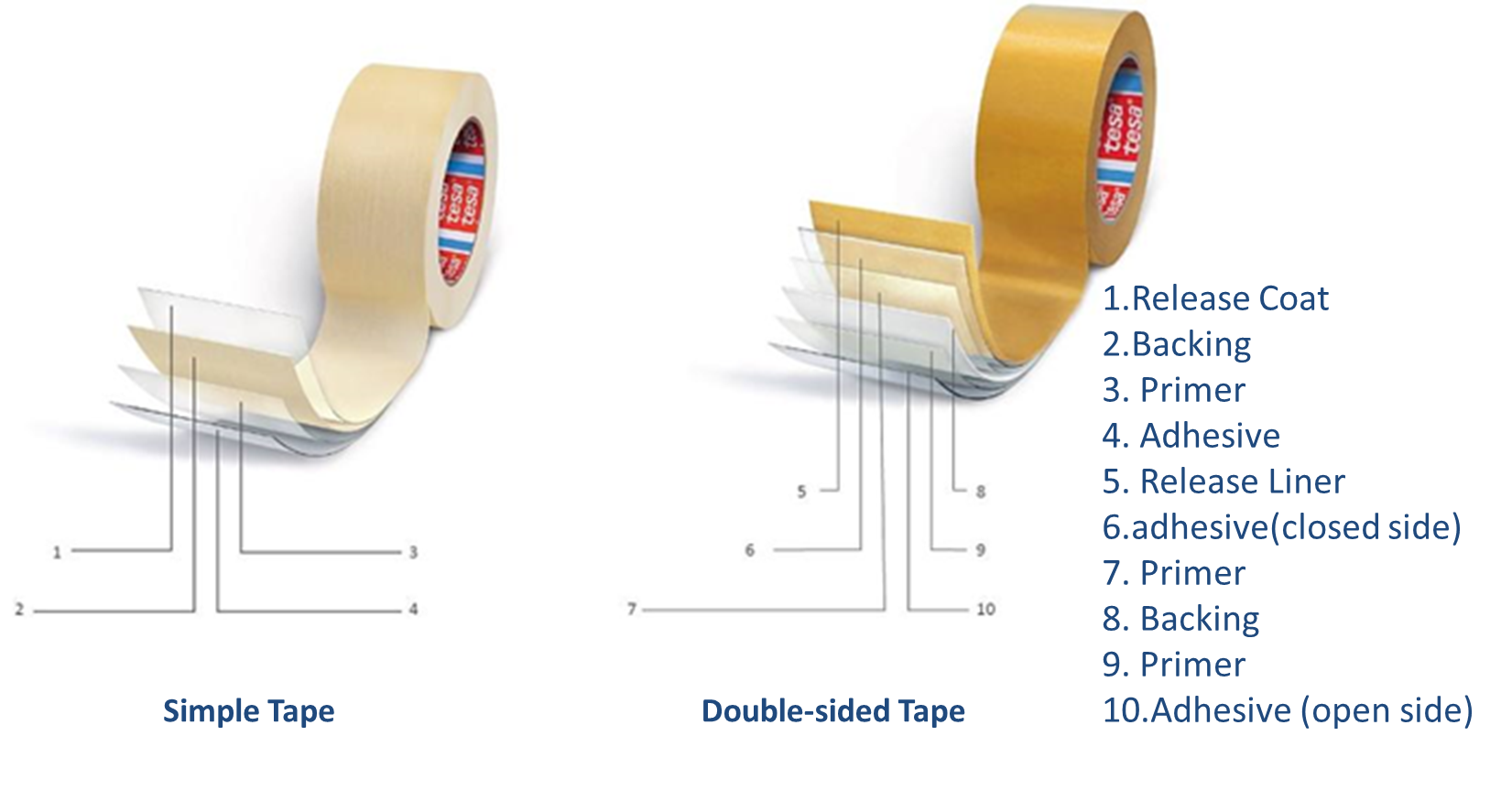

With packaging tape or double-coated tape, a release agent is applied to the back of the tape or the surface of the release liner to enable the tape to be smoothly unrolled or unwinded. Release coating thickness is very low, that they seem invisible.

Release agent provided by Kimya Exir ARISA is in different types: solid or in powder form, water based and solvent based. The best sell release agent from ICHEMCO product range which can be supplied through Kimya Exir ARISA is release K100D. This economic grade is suitable for all kind of adhesive tapes (natural rubber, acrylics, hot-melt).

Primers:

Some kinds of adhesives have limited adhesion on special surfaces. The reason may be due to lower surface energy of substrate in comparison with adhesive. For this reason, primer could be utilized in some cases. In fact, primers usually form a new organic layer in interfaces. The new layer has perfect adhesion on both substrate and adhesive material.

Various kinds of primers including in powder form, solvent based or waterbased is provided by Kimya Exir ARISA.

Antioxidants and UV protectors:

Antioxidants increase resistance of adhesives against oxidation (react with oxygen and free radical forming) while applying, storage and using procedures. Oxidation will cause in degradation process of adhesive. Antioxidants interrupt the degradation in different ways, according to their structure. Some results of adhesive degradation are:

- discoloration

- viscosity changes

- char formation

- cracking and loss of adhesion

Professional grades of anti-oxidant, light stabilizers and UV protectors can be supplied by Kimya Exir ARISA n in different applications such as hotmelt, solvent based and water based adhesive.

Curing agent & cross linker:

Addition of curing agent will improve cohesion, heat resistance, and at the same time, reduce adhesion, peel and tack in adhesive formulation. Curing agent and cross linkers have different types, including: isocyanate, polyaziridine and polyurea

Tackifiers:

Tackifiers are chemical compounds which are used extensively in formulating adhesives. tackifiers increase tack and adhesion of adhesive to substrares. They are usually low-molecular weight compounds with high glass transition temperature.

Tackifiers frequently represent most of both weight percentage and cost of hot melt adhesives and pressure-sensitive adhesives. In hot melt adhesives they can comprise up to about 40% of total mass.

Tackifiers are usually based on rosin esters, hydrocarbon resins and terpenes.

Kimya Exir ARISA represents some kinds of rosin esters and tackifiers suitablr for waterbased adhesives.

Antifoams:

Non-silicone antifoams for water based emulsion adhesives and silicone based defoamers (siloxane based) can be provided by Kimya Exir ARISA.

Pastes and masterbatches for using in tapes:

Inks and additives for flexographic printing on tapes: